Researchers have designed a catalyst using nanotechnology for 3D and electrochemical water treatment which is also used in wastewater treatment of dairy factory.

Hosna Ghanbarlu, the executor of the project “economic synthesis of nanoelectrocatalyst based on Nitrogen doped Graphene for 3D and electrochemical treatment of water resources”, Said: water treatment has been done through various physical and chemical methods, including adsorption, membrane filtration, and photocatalytic removal, biological removal and electrochemical processes.

Pesticides are among the major sources of pollution in groundwater which lead to contaminate potable water due to agricultural measures, because these compounds are absorbed as soon as possible and by penetrating into the subsoil, cause contamination in the aquifers.

These types of contaminants have caused many problems for water treatment all over the world. Although the use of pesticides in the global arena has been severally limited in recent decades, some pesticides residues and their modified products still penetrate into groundwater resources.

The issue of pesticides pollution in European countries is one of the most important issues of urban water treatment. For example, in Denmark, the main focus to remove contaminants is on three pesticide compounds such as 2, 6-dichlorobenzamide, 2-methyl 4-chlorophenoxy acetic acid and mecoprp.

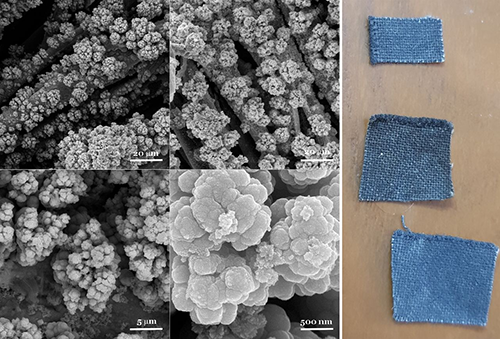

Referring to the catalyst prepared during this project, she said: this catalyst due to have Nitrogen doped Carbon nanostructure, in complex with iron had a high inherent electrochemical activity in electrochemical water treatment; because the structure of Nitrogen doped Graphene improved the activity of Oxygen reduction reaction and iron particles improved Fenton reaction and increased oxidation processes of contaminants.

Ghanbarloo emphasized that the most complex part of this project was how to do catalyst synthesis process with a new method as an innovative idea. However, after determining the general method and precursor for catalyst synthesis, the identification of organic intermediates produced during electrochemical water treatment was one of complex issues of this project. This stage was one of the most important stages of water treatment especially electrochemical treatment of urban potable water.

According to the results of this research, this electrocatalyst can be used in all industries related to sustainable and renewable energy generators such as all types of metal-air batteries, Lithium-ion batteries, fuel cells and electrochemical water treatment systems.

This type of water treatment systems is also applicable for wastewater treatment of dairy factories especially as a pilot plant.

Innovation of this field was the use of low-cost precursors, a simple production method and creation of 3D raspberry-like nanostructure from Nitrogen doped graphene and iron oxide nanocrystals in product catalyst structure.

In some European and American countries, this type of water treatment process is used in factory scale. Unfortunately in Iran, this technology has not been used even in pilot scale, while this method is a green technology and free-pollutant for environment.

Referring to competitive advantages of this project, water treatment process as electrochemical method is a green method with system compaction advantage, no secondary pollution, decentralized application and remote control of the process. Using 3D processes is usually created by adding electrode particles between Anode and Cathode main electrodes (in 2D system).