Chemical engineering researchers have succeeded in developing a biological process in which, halophile bacteria existed in oil fields is used in membrane bioreactors to purify the water produced from Iran’s oil fields.

According to public relations, Nasim Zare, the executor of the project “using membrane bioreactors in water treatment of Iran’s oil fields by use of prokaryotic consortium” said: the wide range of water salinity in the world is reported, but most of oil fields in Iran are high saline.

As there are few studies on bio-treatment of high salinity water and most researchers have focused on synthetic water treatment, she has studied on the real produced water treatment.

The global average of producing water is three times that of oil. As Iran is oil-rich country, the production volume of this wastewater is high in Iran and since our country climate is dry, the need for water is essential; therefor, wastewater treatment with high volume in order to reuse is very significant. The use of native microbial consortium of oil fields was also a new idea which was studied in this project.

As these native sources were selected with this idea that they are compatible with both salinity and petroleum compounds, the analysis of existed compounds in real produced water and output of membrane bioreactor in different situations and comparing them were also considered in this project. The performances of chemical and biological treatment methods were also compared.

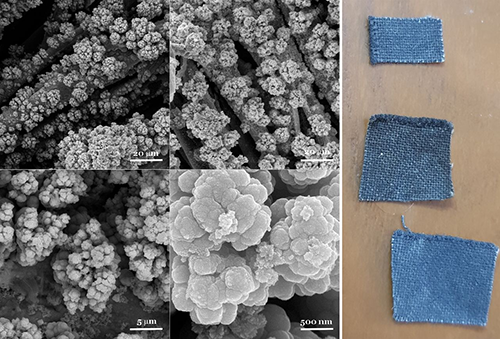

She emphasized that the microbial identification of the selected consortium made it possible to study the capability of existing microorganisms and their optimal growth and performance conditions according to biological studies on halophile microorganisms. This analysis showed that in the degree of salinity used, bacteria have more species richness and diversity compared to archaea, as well as a wide range of salt tolerance and ability to biodegradate hydrocarbons by identified bacteria implied that potential of selected consortium has been used in water treatment.

Referring to some results of this project, the study of biological water treatment on membrane bioreactor, made it possible to conduct more experiments. At this stage, it was showed that with increasing hydraulic retention time along with reducing organic load rate, the removal percentage of TOC and COD decreased. Adding yeast extract with concentration of 0.01% also increased microbial growth and removal percentage of COD and the adding of glycine betaine as an osmotic compatibility substance leads to significant increase in biomass concentration.

The analysis of gas chromatography-mass spectrophotometry of produced and output water of membrane bioreactor in different stages of data analysis was very effective. Identifying substances in output wastewater showed that some substances identified in previous studies were introduced as soluble microbial products.

The project features are preparation of native halophile consortium in high-salt oil field and its microbial identifying, investigating the performance of halophile consortium in membrane bioreactor in treatment of high-salt real produced water, investigating removal of contaminants in produced water in membrane bioreactor through GC/MS method, comparing general removal parameters (TOC and COD) by removing contaminants through GC/MS method.

In this research, treatment process of high-salt real produced water was developed by using native microbial consortium of oil field. It is the first time that such research is done in Iran and its difference with foreign researches is that the biological treatment of real high-salt produced water in membrane bioreactor was developed by using native microbial halophile consortium of Iran’ oil storages.

According to the competitive advantages of the project, by conducting additional experiments in this study for use in industry, use of native consortium of oil field has this advantage which this microbial source is available and needs low compatibility time compared to other microbial sources which are separated from saline environments and if there is a problem in biological treatment system, it can be easily replaced. Also, the other reasons making this method significant are the environmental advantages of biological methods, cost reduction compared to chemical methods needed to contaminants and expensive materials and high quality of wastewater in membrane science.